近日,陜西科技大學(xué)化學(xué)與化工學(xué)院黃文歡教授團(tuán)隊(duì)在Advanced Functional Materials期刊發(fā)表題為“Ultra-Low 4.3 wt% Silicon Thermal Reducing Doped Porous Si@MoC as Highly Capable and Stable Li-Ion Battery Anode”的研究論文�����,博士生陳卓為論文的第一作者�。

由于電動汽車和設(shè)備的能源需求嚴(yán)峻,開發(fā)高能量��、長循環(huán)壽命的鋰離子電池具有重要意義����。硅作為鋰電池的新一代負(fù)極材料,以其高達(dá)約4200 mAh g?1的理論比容量和豐富的自然資源而備受關(guān)注����。然而,硅在充放電多孔過程中不可避免的劇烈體積膨脹(≈300%)不僅削弱了電極和集流體的接觸����,還導(dǎo)致了不穩(wěn)定的固體電解質(zhì)間相(SEI)的形成。不可逆的容量退化和電池壽命的縮短被認(rèn)為是阻礙其商業(yè)化的主要限制。

一般情況下�,采用碳?xì)ぐ补杓{米顆粒的方式來減輕硅膨脹問題。然而�,在電池循環(huán)過程中,電解質(zhì)離子必須穿透碳?xì)?��,然后與硅反應(yīng)���,導(dǎo)致動力學(xué)效果不佳�����。碳基質(zhì)也會存在不必要的結(jié)構(gòu)變化�。此外,高負(fù)載硅納米顆粒的聚集會導(dǎo)致硅的利用效率低���,從而影響電池的長期性能��。迄今為止��,開發(fā)和設(shè)計高利用率的硅碳負(fù)極材料仍然是一個巨大的挑戰(zhàn)�����。

鑒于此�,黃文歡教授團(tuán)隊(duì),采用ZnMo雙金屬雜化沸石咪唑酸鹽框架(HZIF-ZnMo)����,開發(fā)和設(shè)計了一種超低4.3 wt%的硅摻雜多孔MoC材料,并進(jìn)一步探索了其在高容量鋰離子電池中的潛力(在0.2 A g?1下進(jìn)行250次循環(huán)后�����,容量為976.6 mAh g?1)��。研究表明����,多孔MoC作為基底,不僅為鋰離子的快速擴(kuò)散提供了連續(xù)的通道�,還使超低含量的硅在多孔基體中高度均勻分布,有效誘導(dǎo)硅在循環(huán)過程中實(shí)現(xiàn)自身容量的最大利用����,研究成果發(fā)表于學(xué)術(shù)期刊Advanced Functional Materials,題為“Ultra-Low 4.3 wt% Silicon Thermal Reducing Doped Porous Si@MoC as Highly Capable and Stable Li-Ion Battery Anode”

文章要點(diǎn)

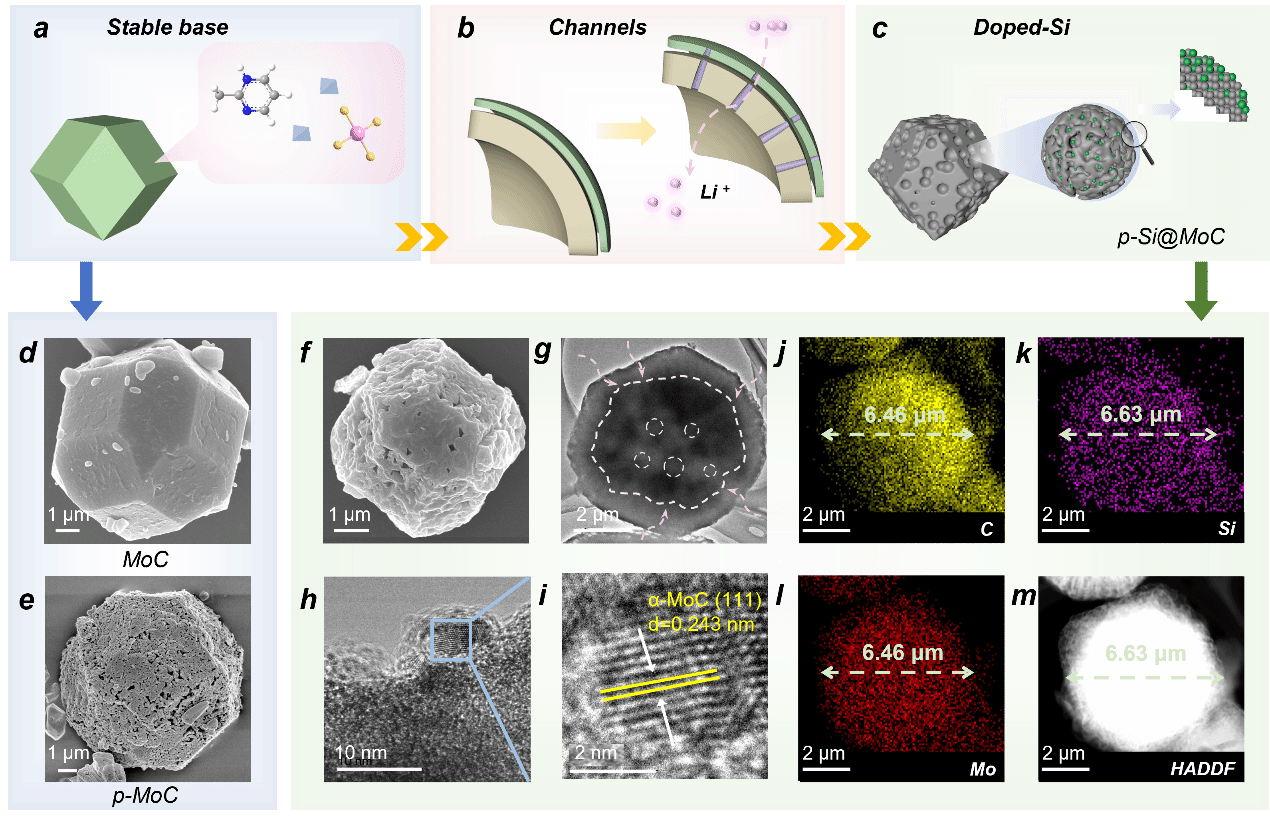

要點(diǎn)一:利用HZIF-ZnMo合成多孔Si@MoC(p-Si@MoC)

首先����,利用水熱法合成了HZIF-ZnMo�����。隨后�,通過將TEOS涂覆在HZIFZnMo上制備SiO2@HZIF-ZnMo����,通過將正硅酸乙酯包覆在HZIF-ZnMo上制備SiO2@HZIF-ZnMo,通過簡單的熱還原��,構(gòu)建了超低約4.3 wt%摻雜Si的MoC多孔結(jié)構(gòu)�����。反應(yīng)保留了ZnMo咪唑框架的多面體結(jié)構(gòu)并促進(jìn)Si在多孔MoC基體內(nèi)的均勻分散��。此外����,為了研究Si和多孔結(jié)構(gòu)在p-Si@MoC中的作用���,我們還合成了多孔MoC(p-MoC)和非多孔MoC�����,并在后續(xù)的實(shí)驗(yàn)中組裝成電池����,進(jìn)行比較。

圖1 多孔Si@MoC材料設(shè)計及合成

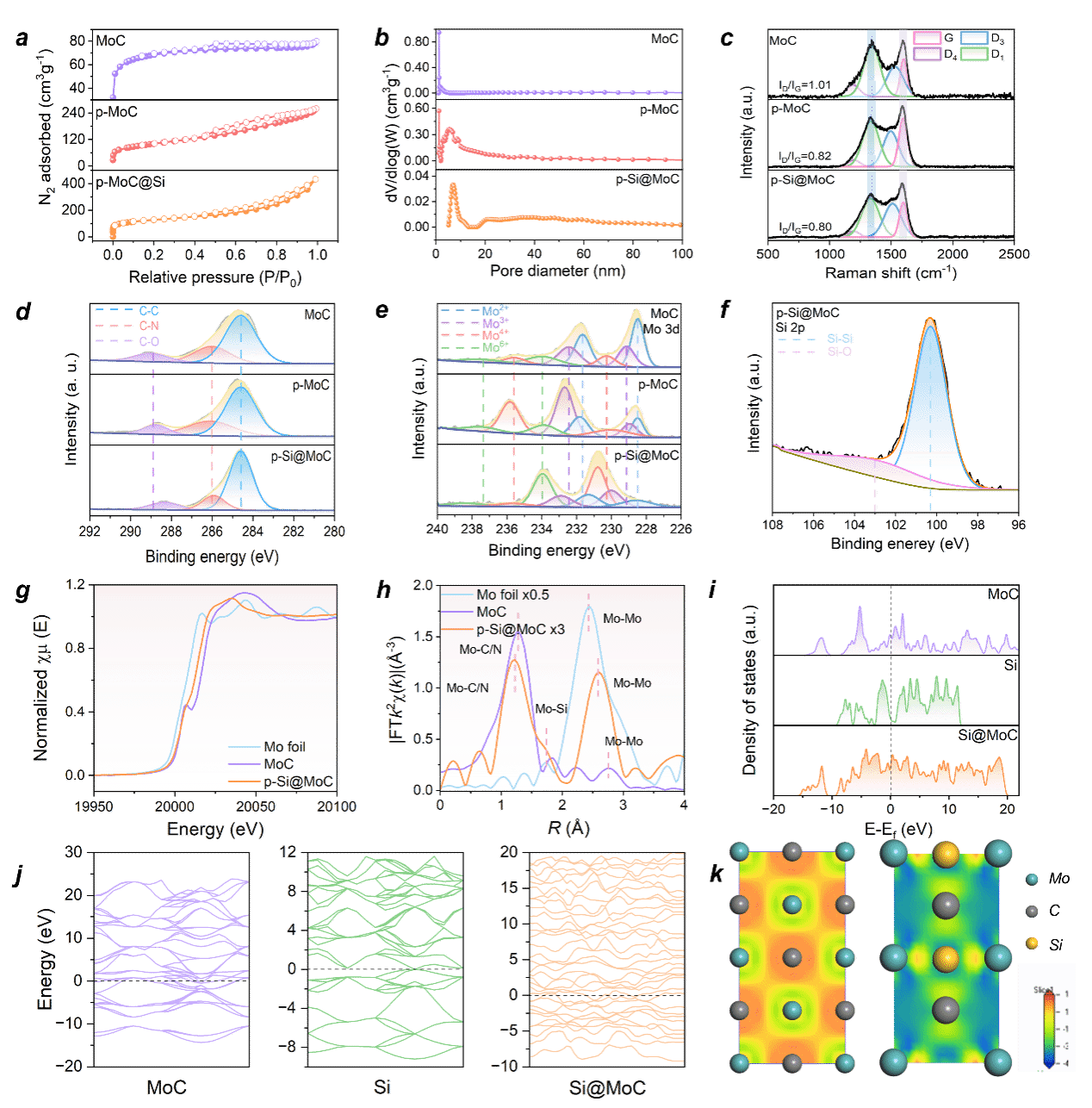

圖2 多孔Si@MoC的表征

通過X射線近邊吸收光譜(XANES)和擴(kuò)展X射線吸收精細(xì)結(jié)構(gòu)譜(EXAFS)��,驗(yàn)證了Si摻雜在MoC基體中形成的Mo-Si鍵�。通過密度泛函理論(DFT)的計算,揭示了多孔Si@MoC優(yōu)異的電導(dǎo)率和電子傳遞能力�。

要點(diǎn)二:超低含量摻雜有效地誘導(dǎo)Si在p-Si@MoC中最大容量利用率

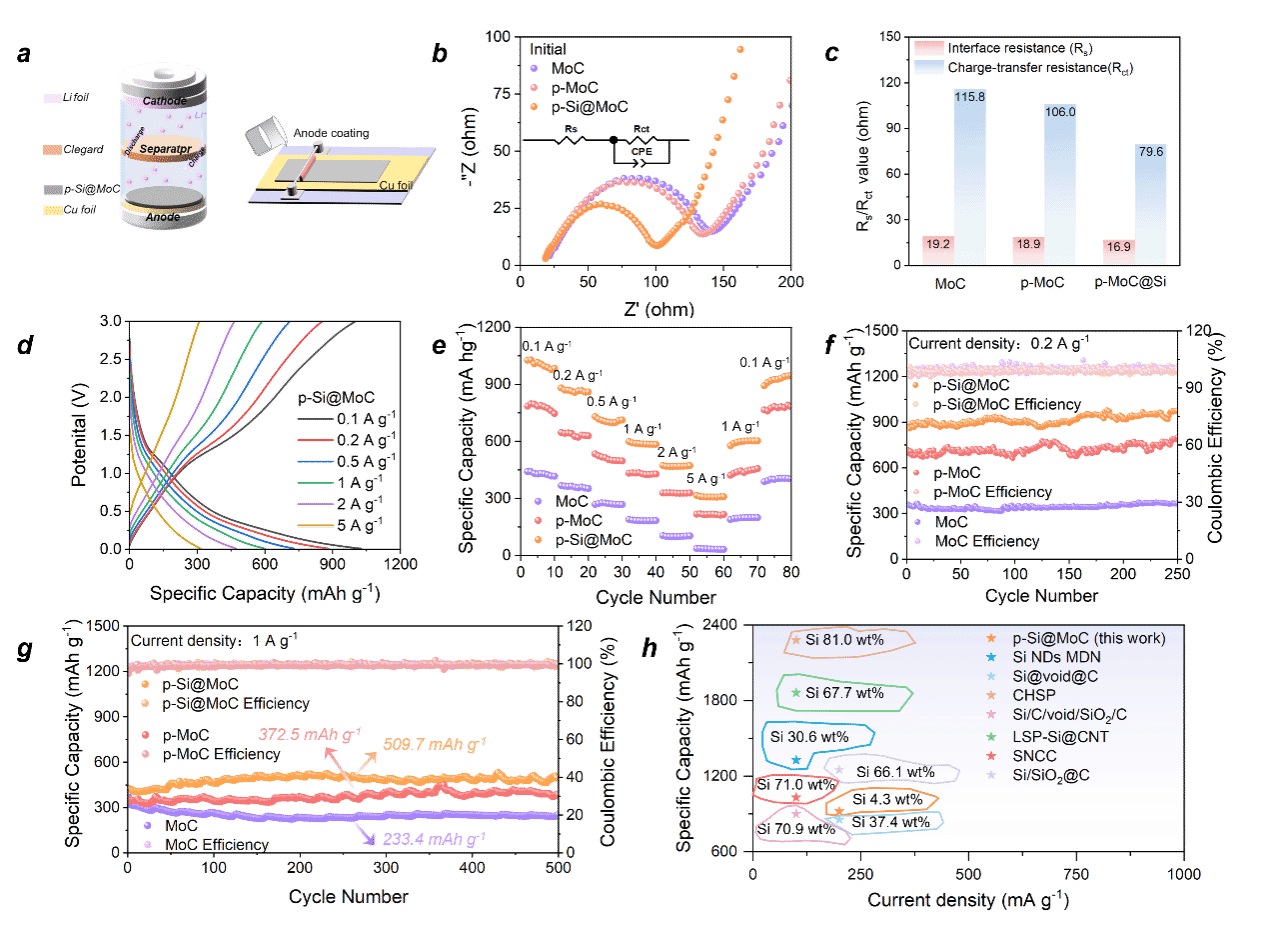

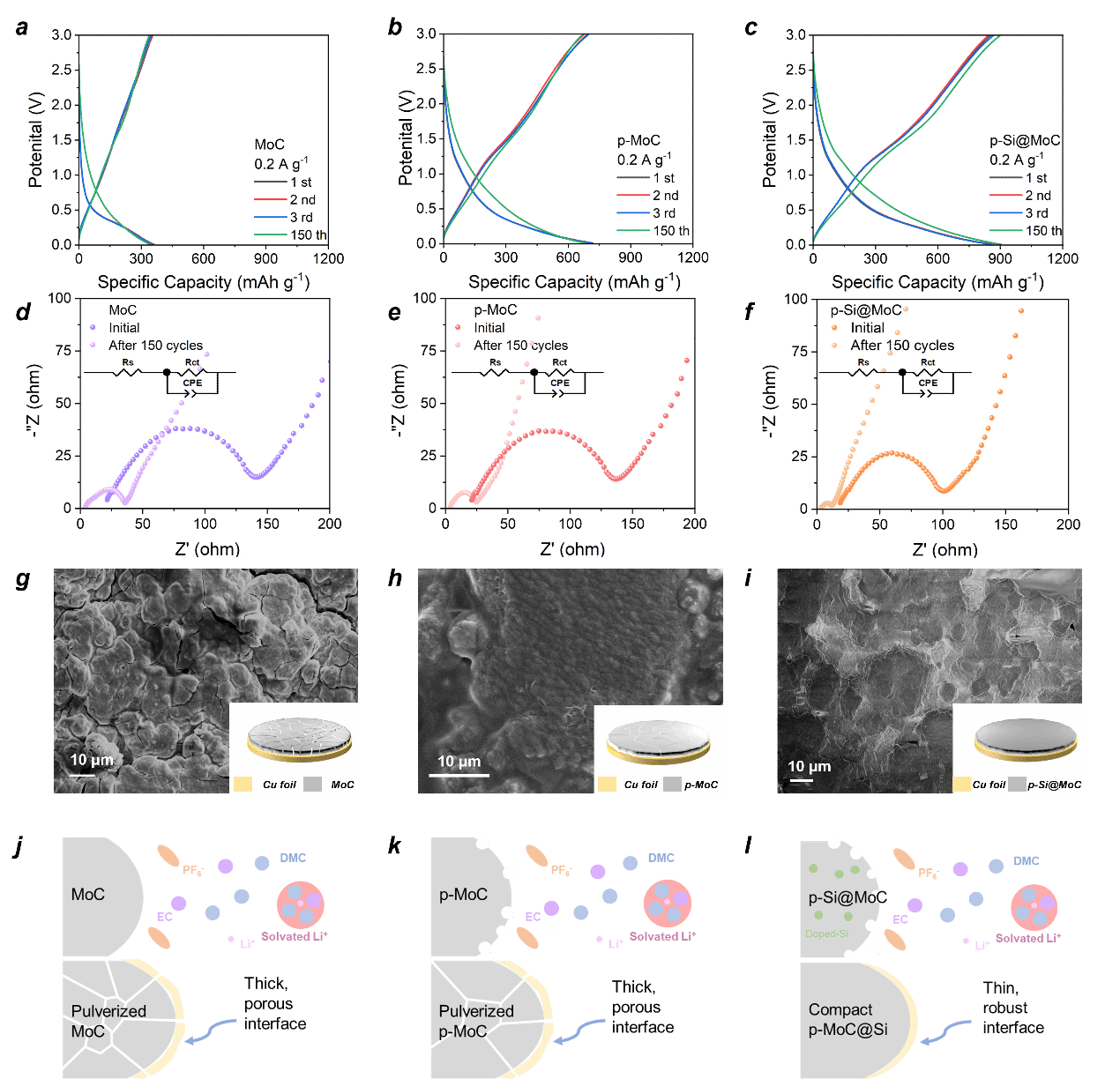

作為鋰離子電池負(fù)極材料,p-Si@MoC展現(xiàn)出了極小的電極/電解質(zhì)界面阻抗(Rs)和電荷轉(zhuǎn)移阻抗(Rct)�。值得注意的是,優(yōu)化后p-Si@MoC負(fù)極在250次循環(huán)后顯示976.6 mAh g-1的放電容量�����,而p-MoC在250次循環(huán)后的放電容量為800.6 mAh g-1��。根據(jù)p-Si@MoC中Si的含量(4.3 wt%)計算出硅的理論容量為180.6 mAh g-1��。因此��,我們認(rèn)為這種獨(dú)特的多孔結(jié)構(gòu)可以最大限度地利用Si摻雜來提高容量�����,且Si的容量利用率可達(dá)97.5%。

為了進(jìn)一步評估p-Si@MoC的循環(huán)穩(wěn)定性��,在1 A g?1的電流密度下進(jìn)行500圈次循環(huán)后����,p-Si@MoC的可逆容量保持在485.8 mAh g?1,庫侖效率(CE)為98.9%����。相比之下,p-MoC和MoC在500次循環(huán)后的放電容量分別為385.1和249.6 mAh g?1��。值得注意的是�,p-Si@MoC負(fù)極的高放電容量歸因于硅的摻雜和基體的多孔結(jié)構(gòu)。與最近報道的不同成分和結(jié)構(gòu)的硅基負(fù)極材料相比�����,p-Si@MoC中硅的含量更低�����。更重要的是��,p-Si@MoC具有優(yōu)異的電化學(xué)性能�����,但仍可與其他硅基陽極相媲美�。

圖3 多孔Si@MoC電池性能測試

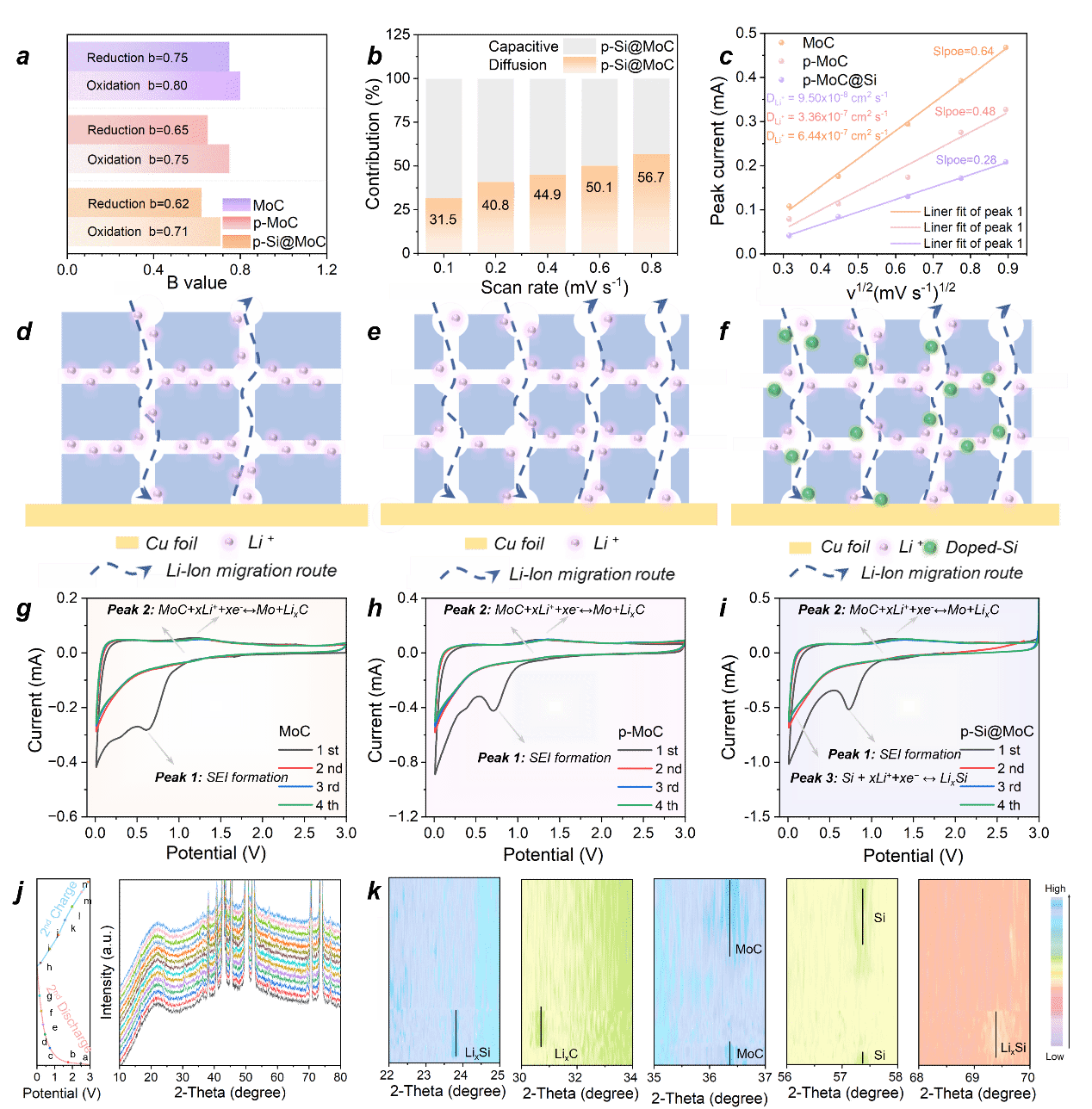

要點(diǎn)三:p-Si@MoC材料促進(jìn)鋰離子快速動力傳輸及原位儲鋰機(jī)制

p-Si@MoC材料引起具有的良好的孔結(jié)構(gòu)和高度均勻分散的Si,使p-Si@MoC在重復(fù)鋰化/脫鋰的過程中仍保持優(yōu)異的結(jié)構(gòu)穩(wěn)定性�,電極表面薄且致密。MoC���、p-MoC和p-Si@MoC電極在經(jīng)歷150次循環(huán)前后的電化學(xué)阻抗也證明了p-Si@MoC具有優(yōu)異的結(jié)構(gòu)穩(wěn)定性����。對比循環(huán)前后多孔Si@MoC負(fù)極變化�,膨脹率僅有11.6%。因其獨(dú)特的多孔結(jié)構(gòu)���,在整個過程中與硅保持著密切接觸�,有效地吸收了循環(huán)過程中硅顆粒增加的體積���,減輕體積膨脹�����。此外���,對電化學(xué)動力學(xué)過程進(jìn)行研究�����,p-Si@MoC負(fù)極較高的鋰離子擴(kuò)散系數(shù)(6.44×10?7 cm2 s?1)證實(shí)了多孔MoC構(gòu)建的提供豐富的孔隙和離子開放通道����,有利于電解液的滲透和鋰離子的擴(kuò)散���。

原位XRD測試結(jié)果顯示��,顯示了在放電和充電過程中多孔MoC基體變化(MoC + xLi+ + xe? → Mo + LixC�����,放電過程中的反應(yīng))和LixSi的形成與解離���,與CV曲線一致,證實(shí)了電極在循環(huán)過程中電化學(xué)的高度可逆性�����。

圖4 多孔Si@MoC電極表面穩(wěn)定性研究

圖5 多孔Si@MoC電極動力傳輸及原位儲鋰機(jī)制

文章鏈接

Ultra-Low 4.3 wt% Silicon Thermal Reducing Doped Porous Si@MoC as Highly Capable and Stable Li-Ion Battery Anode

Adv. Funct. Mater. 2024, 2314176

https://doi.org/10.1002/adfm.202314176

附:團(tuán)隊(duì)近三年部分代表性論文:

[1] W. Huang*, S. Wang, X. Zhang, Y. Kang, H. Zhang*, N. Deng, Y. Liang, H. Pang*, Universal F4-modified Strategy on Metal Organic Framework to Chemical Stabilize PVDF-HFP as Quasi-Solid-State Electrolyte, Advanced Materials, 2023, 35(52), 202310147.

[2] Z. Chen, X. Lu, Y. Zhang,* Y. Kang, X. Jin,* X. Zhang, Y. Li, H. Wang,* and W. Huang*, Ultra-low 4.3 wt% silicon thermal reducing doped porous Si@MoC as highly capable and stable Li-ion battery anode, Advanced Functional Materials, 2024, DOI:10.1002/adfm.202314176.

[3] X. Zhang, Q. Su*, G. Du, B. Xu, S. Wang, Z. Chen, L. Wang, W. Huang*, H. Pang*, Stabilizing Solid-state Lithium Metal Batteries through In Situ Generated Janus-heterarchical LiF-rich SEI in Ionic Liquid Confined 3D MOF/Polymer Membranes, Angew Chem. Int. Ed., 2023, 62(39), 202304947.

[4] W. Huang, C. Su, C. Zhu, T. Bo, S. Zuo, W. Zhou, Y. Ren, Y. Zhang, J. Zhang, M. Rueping*, H. Zhang*, Isolated Electron Trap-Induced Charge Accumulation for Efficient Photocatalytic Hydrogen Production, Angew Chem., Int. Ed., 2023, 62 (25), 202304634.(VIP paper)

[5] W. Huang,* X. Zhang, J. Chen, Q. Qiu, Y. Kang, K. Pei, S. Zuo, and R. Che*, High-density Nanopore Confined Vortical Dipoles and Magnetic Domains on Hierarchical Macro/Meso/Micro/Nano Porous Ultra-Light Graphited Carbon for Adsorbing Electromagnetic Wave, Advanced Science, 2023, 2303217.

[6] X. Zhang, W. Huang*, L. Yu, M. García-Melchor, D. Wang, L. Zhi* and H. Zhang* Enabling Heterogeneous Catalysis to Achieve Carbon Neutrality: Directional Catalytic Conversion of CO2 into Carboxylic Acids, Carbon Energy, 2023, e362.

[7] W. Huang, T. Bo, S. Zuo, Y. Wang, J. Chen, S. Ould‐Chikh, Y. Li, W. Zhou*, J. Zhang, H. Zhang*, Surface decorated Ni sites for superior photocatalytic hydrogen production, Susmat, 2022, 2(4) 466-475.

[8] C. Feng, Y. Ren, F. Razq, W. Huang*, H. Zhang*, An innovative and ingenious strategy to construct single-atom catalyst for photocatalytic methane conversion, Matter, 2022, 5, 3086–3111.

[9] M. Sun, W. Cao, P. Zhu, Z. Xiong, C. Chen, J. Shu*, W. Huang*, Fan Wu*, Thermally tailoring magnetic molecular sponges through self-propagating combustion to tune magnetic-dielectric synergy towards high-efficiency microwave absorption and Attenuation, Advanced Composites and Hybrid Materials, 2023, 6: 54.

[10] Y. Ren, W. Huang*, M.A. Alsuhami, H. Zhang, J. Ye*, Subsurface engineering for efficient photocatalytic water splitting, Chem Catalysis, 2023, 3(8), 100707.

[11] P. Li, Z. He, X. Li, W. Huang*, and X. Lu*, Fullerene-Intercalated Graphitic Carbon Nitride as a High-Performance Anode Material for Sodium Ion Batteries. Energy & Environmental Materials, 2022, 5: 608–616.

[12] W. Huang*, Q. Qiu, X. Yang, S. Zuo, J. Bai, H. Zhang*, K. Pei and R. Che*, Ultrahigh Density of Atomic CoFe-Electron Synergy in Noncontinuous Carbon Matrix for Highly Efficient Magnetic Wave Adsorption. Nano-Micro Letters, 2022, 14(1): 96.

[13] W. Huang*, W. Gao, S. Zuo, L. Zhang, K. Pei, P. Liu and R. Che*, and H. Zhang*, Hollow MoC/NC Sphere for Electromagnetic Wave Attenuation: Direct Observation of Interfacial Polarization on Nanoscale Hetero-interfaces. Journal of Materials Chemistry A, 2022, 10: 1290-1298.(雜志封面Outside Front Cover)(高被引論文)

[14] Y. Kang, J. Tang, J. Chen, M. Song, W. Wang, T. Liu, W. Huang*, “Appropriate dressing” non-fluorination strategy: Dopamine coating CuSiF6 framework derived F-rich SiC/CuF2@C electromagnetic wave absorber, Carbon, 2024, 218, 118690.

[15] W. Huang*, J. Chen, W. Gao, L. Wang, P. Liu*, Y. Zhang, Z. Yin, Y. Yang, “Host-Guest” crystalline Mo/Co-framework induced phase-conversion of MoCx in carbon hybrids for regulating absorption of electromagnetic wave, Carbon, 2022, 197: 129-140.

[16] W. Huang*, S. Wang, X. Yang, X. Zhang, Y. Zhang, K. Pei, R. Che*, Temperature induced transformation of Co@C nanoparticle in 3D hierarchical core-shell nanofiber network for enhanced electromagnetic wave adsorption, Carbon, 2022, 195: 44-56.

[17] Y. Zhang, J. Chen, C. Su, K. Chen, H. Zhang, Y. Yang, W. Huang*, Enhanced ionic diffusion interface in hierarchical metal-organic framework@layered double hydroxide for high-performance hybrid supercapacitors, Nano Research, 2022, 15(10), 8983-8990.

[18] W. Huang*, X. Li, X. Yang*, H. Zhang, P. Liu, Y. Ma, and X. Lu, CeO2-embedded mesoporous CoS/MoS2 as highly efficient and robust oxygen evolution electrocatalyst. Chemical Engineering Journal, 2021, 420: 127595.

[19] Y. Li, X. Jin*, Y. Ma, L. Ma, J Liu, P. Zhu, Z. Deng, H. Zhou, W Chen, W. Huang*, Functional decoration on a regenerable bifunctional porous covalent organic framework probe for the rapid detection and adsorption of copper ions, Rare Metals, 10.1007/s12598-023-02476-w.

[20] Y. Zhang, J. Chen, F. Razq, C. Su, X. Hou, W. Huang*, and H. Zhang*, Polyoxometalate-incorporated host-guest framework derived layered double hydroxide composites for high-performance hybrid supercapacitor, Chinese Journal of Chemistry, 2023, 41, 75-82. (雜志封面Outside Front Cover)

[21] X. Yang, W. Gao, J. Chen, X. Lu, D. Yang, Y. Kang, Q. Liu, Y. Qing, and W. Huang*, Co-Ni Electromagnetic Coupling in Hollow Mo2C/NC Sphere for Enhancing Electromagnetic Wave Absorbing Performance, Chinese Journal of Chemistry, 2023, 41, 64-74.

[22] W. Huang*, X. Li, X. Yang*, X. Zhang, H. Wang, H. Wang, The recent progress and perspectives on the metal- and covalent- organic frameworks based solid-state electrolytes for lithium-ion batteries. Materials Chemistry Frontiers, 2021, 5 (9): 3593-3613.

新聞小貼士:

黃文歡���,主要從事多氮唑雜化框架的設(shè)計合成����,能源存貯及轉(zhuǎn)化���、電磁波吸收屏蔽�����、固態(tài)電池關(guān)鍵材料的應(yīng)用研究���。入選“2023年度全球前2%頂尖科學(xué)家榜單”,陜西省特支計劃-青年拔尖人才���、陜西省“科學(xué)家+工程師”創(chuàng)新團(tuán)隊(duì)首席科學(xué)家�、陜西省科技新星�,近年來主持國家項(xiàng)目2項(xiàng)、省部級各類科研項(xiàng)目11項(xiàng)�、教學(xué)項(xiàng)目4項(xiàng),獲得陜西省高??茖W(xué)技術(shù)獎一等獎(第1完成人)1項(xiàng),陜西省人才計劃項(xiàng)目4項(xiàng)��。在Angew Chem. Int. Ed.、Advanced Materials�����、Advanced Functional Materials����、Advanced Science、Nano-Micro Letters�����、Carbon Energy����、Matter、Journal of Materials Chemistry A�����、Energy & Environmental Materials�、Chemical Engineering Journal等國際期刊上發(fā)表SCI論文50余篇,其中受邀撰寫綜述6篇�����,高被引論文7篇,熱點(diǎn)論文2篇�����。授權(quán)國家發(fā)明專利10余件����,其中4件實(shí)現(xiàn)企業(yè)轉(zhuǎn)化���。曾受邀請?jiān)趪鴥?nèi)外學(xué)術(shù)會議上作報告20余次���,媒體轉(zhuǎn)載相關(guān)研究成果20余次。組織學(xué)生參加“挑戰(zhàn)杯”課外學(xué)術(shù)科技競賽獲得省級二等獎2項(xiàng)��、三等獎1項(xiàng)����,獲得陜西省第六屆研究生創(chuàng)新成果展省級一等獎1項(xiàng),省級創(chuàng)新基金1項(xiàng)����;培養(yǎng)研究生獲得“優(yōu)秀畢業(yè)生”、“優(yōu)秀碩士畢業(yè)論文”、“國家獎學(xué)金”����、“研究生高水平科研成果獎勵”等。

(核稿:黃文歡 編輯:王舒婷)